In the field of industrial material handling, vibrating conveyors are widely used in mining, metallurgy, chemicals, food, and other industries due to their high efficiency, low maintenance, and adaptability to complex working conditions. As a specialized manufacturer of equipment steel structures in China, Jiaxing Dingshi Machinery Manufacturing Co., Ltd leverages advanced production equipment and a skilled technical team to provide customized mechanical structure design and performance optimization solutions for vibrating conveyors, helping customers improve conveying efficiency and equipment reliability.

1. Customized Mechanical Structure Design Services

We offer non-standard vibrating conveyor structural designs based on customer requirements (such as material characteristics, throughput, and spatial constraints), including:

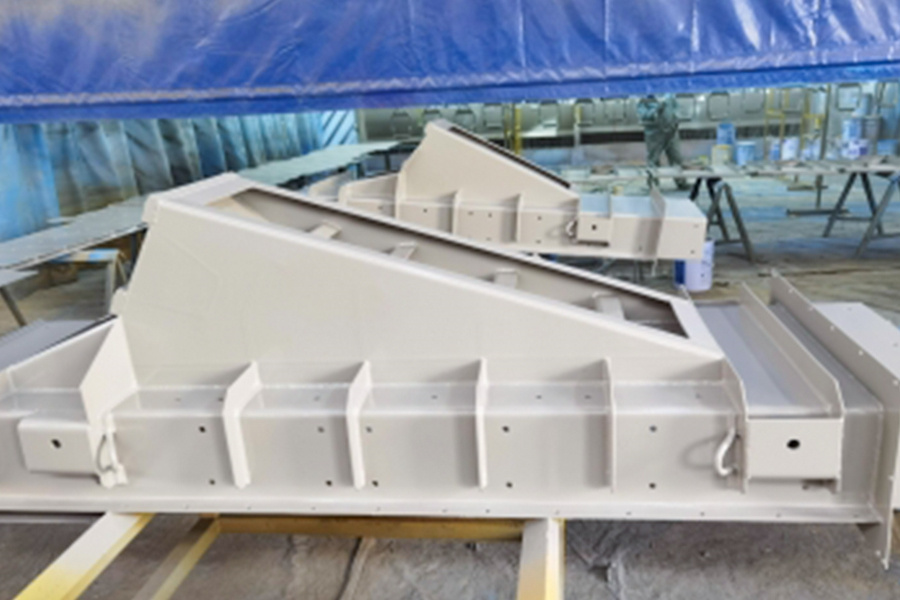

- Frame Optimization: High-strength steel construction ensures stability under long-term vibration conditions.

- Customized Damping Systems: Matches amplitude and frequency requirements to reduce impact on foundation structures.

- Modular Design: Facilitates installation, maintenance, and future expansion, lowering operational costs.

2. High-Performance Manufacturing Process Assurance

With fixed assets exceeding RMB 25 million, we utilize advanced equipment to ensure machining precision and structural strength:

- Laser Cutting (30kW/20kW): High-precision blanking for consistent components.

- 600-ton Press Brake & Gantry Machining Centers (4m/6m): Ensures precise forming of large structural parts.

- Welding & Surface Treatment: 50 welding machines support various welding techniques, while a 30-meter shot blasting machine and 300㎡ paint booth ensure corrosion resistance and durability.

3. Key Solutions for Performance Enhancement

To address common issues such as wear, noise, and efficiency degradation, we provide:

- Material Upgrades: Wear-resistant steel plates or specialized coatings extend the lifespan of critical components.

- Dynamic Balance Optimization: Adjusts exciter configurations through simulation analysis to reduce energy consumption and vibration transmission.

- Smart Monitoring Integration: Optional sensors for real-time monitoring of amplitude, temperature, and other parameters to prevent failures.

4. One-Stop Service Advantage

From raw material cutting and forming to welding, painting, and assembly, we offer full-cycle manufacturing services, ensuring controlled delivery timelines and quality. In 2023, the company achieved an output value of RMB 120 million, with continuous innovation from our technical team to meet global customer demands for high-reliability vibrating conveyors.

For further technical solutions or case references, please contact Jiaxing Dingshi Machinery Manufacturing Co., Ltd, and we will provide professional support.

Key Design Points for Hygienic Structures of Food/Pharmaceutical Grade Vibrating Conveyors

In the food and pharmaceutical industries, the structural design of vibrating conveyors must comply with strict hygiene standards (such as FDA, GMP, etc.). Leveraging our expertise in specialized equipment steel structure manufacturing, Jiaxing Dingshi Machinery Manufacturing Co., Ltd provides vibrating conveyor solutions that meet the hygiene requirements of the food and pharmaceutical sectors.

1. Material Selection

- Use of 304/316L food-grade stainless steel materials

- All material-contact parts utilize non-toxic, corrosion-resistant materials

- Special coating treatments available for non-contact areas

2. Structural Design

- Fully welded frame structure to avoid hygiene dead zones from bolted connections

- All corners feature large-radius transition design (R≥10mm)

- Removable cover plate design for easy internal cleaning

- Tool-free quick-disassembly mechanisms

3. Surface Treatment

- Mirror polishing for contact surfaces (Ra≤0.8μm)

- Pre-treatment using 30-meter shot blasting machine

- 300㎡ paint booth ensures uniform coating

- Optional special treatment processes like electropolishing

4. Cleaning Validation

- Provision of material certificates and surface roughness test reports

- Assistance available for customer cleaning validation (CIP/SIP)

- Design incorporates drainage slopes to prevent water accumulation

5. Manufacturing Advantages

Jiaxing Dingshi Machinery Manufacturing Co., Ltd possesses:

- Specialized stainless steel processing equipment (laser cutting, bending, etc.)

- 50 various welding machines to ensure welding quality

- Complete surface treatment production line

- 70㎡ curing room to guarantee coating quality

We provide food and pharmaceutical enterprises with one-stop services from design and manufacturing to validation, ensuring vibrating conveyors meet stringent hygiene requirements. With an annual output value of RMB 120 million in 2023, our company has accumulated rich industry experience and technical expertise.