Key Component Analysis: Selection, Maintenance and Performance Optimization of Mining Crushers and Conveyor Belts

In mining operations, crushers and conveyor belts serve as core equipment in material handling, with their operational status directly impacting overall production line efficiency, cost control and safety. This article provides a systematic technical reference for mining equipment managers through three dimensions: selection principles, maintenance management and performance optimization, aiming to achieve efficient and stable equipment operation.

1. Selection Principles: Ensuring Precise Matching Between Equipment and Working Conditions

(1) Core Considerations for Crusher Selection

Crusher selection requires comprehensive evaluation of multiple factors including material characteristics, production requirements and operating environment. The hardness, moisture content and initial particle size of materials determine the crusher type - for instance, high-hardness ores typically require jaw crushers for primary crushing, while medium-hardness materials are more suitable for cone crushers or impact crushers for secondary crushing. Production capacity needs directly determine equipment specifications, requiring selection of appropriate processing capacity based on mine production scale to avoid overload operation or idle capacity. Energy efficiency is another crucial factor, as different crushing principles (such as impact crushing or compressive crushing) show significant differences in power consumption, requiring comprehensive evaluation combined with electricity costs. Finally, the material selection of wear parts directly affects maintenance costs, with materials like high manganese steel, alloy steel or composite ceramics significantly extending replacement cycles.

(2) Key Parameters for Conveyor Belt Selection

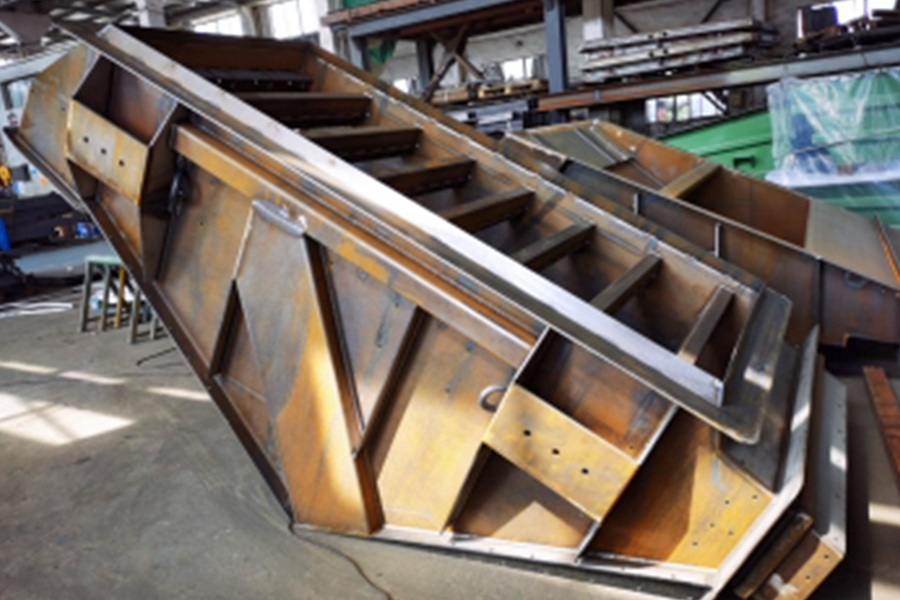

Conveyor belt selection should focus on load capacity, environmental adaptability and structural design. Load capacity mainly depends on the matching of belt width and speed - for example, high-volume material transportation typically requires belts wider than 1200mm combined with speeds of 1.5-3.5m/s to ensure efficiency. For environmental adaptability, humid underground conditions or high-temperature environments require special rubber-covered belts to prevent corrosion or aging. Structural design should be flexibly adjusted according to material characteristics - powdered materials suit trough-shaped belts to prevent spillage, while large ores require reinforced skeleton layers for improved impact resistance.

2. Maintenance Management: Preventive Maintenance to Reduce Unplanned Downtime

(1) Systematic Maintenance Strategy for Crushers

Stable crusher operation relies on regular lubrication management, wear monitoring and fault warning. The lubrication system is critical for equipment longevity, requiring regular inspection of bearing and gearbox oil levels and quality, with strict adherence to standard grease replacement schedules to prevent component wear caused by poor lubrication. Meanwhile, wear part condition monitoring is essential - regular measurement of jaw plates, hammers or liner thickness should be conducted, with timely replacement when reaching critical wear levels to prevent performance degradation or sudden failures. Additionally, abnormal vibration or noise often indicates potential problems, requiring timely troubleshooting of rotor imbalance or bearing damage through vibration analysis to prevent minor issues from developing into major repairs.

(2) Precise Maintenance Points for Conveyor Belts

Conveyor belt maintenance focuses on preventing misalignment, joint failure and material accumulation. Misalignment is a common conveyor issue requiring regular inspection of roller and pulley alignment, with timely correction through tensioning devices to avoid edge wear and premature damage. Joint reliability is equally crucial - whether vulcanized or mechanical joints require regular inspection for cracks or delamination to ensure connection strength meets operational requirements. Furthermore, material residue not only accelerates return belt wear but may also cause pulley slippage, necessitating effective cleaning devices (such as scrapers or cleaners) to maintain system cleanliness.

3. Performance Optimization: Technological Innovation Driving Efficiency Improvement

(1) Energy Efficiency and Lifespan Optimization for Crushers

Crusher performance optimization can focus on three aspects: chamber design, intelligent control and wear technology. Chamber design improvements can optimize the nip angle between movable and fixed jaws, thereby increasing reduction ratio while reducing energy consumption. Intelligent control technology further enhances operational efficiency - for example, real-time monitoring of crushing force through load sensors and automatic feed rate adjustment to prevent overload or idling. In wear technology, solutions like hardfacing repair or composite ceramic liners can significantly extend wear part lifespan and reduce replacement frequency.

(2) Intelligentization and Reliability Enhancement for Conveyor Belts

Conveyor belt optimization includes energy-saving drives, anti-tear design and automated monitoring. Energy-saving drive technology (such as VFD motors) can dynamically adjust operating speed based on actual load, reducing power consumption during low-load periods. Anti-tear design reinforces skeleton layers (like steel cord) or adds transverse reinforcements to effectively reduce accidental breakage risks. Additionally, automated monitoring systems (including tension sensors and crack detectors) enable real-time condition monitoring and timely warning of abnormalities, providing data support for preventive maintenance.

Scientific management of mining crushers and conveyor belts requires coordinated advancement in three aspects: selection, maintenance and optimization. Precise selection forms the foundation of efficient operation, preventive maintenance minimizes unexpected failures, while technological innovation enables continuous performance improvement. Through systematic management strategies, mining enterprises can significantly enhance equipment reliability, optimize production costs, and ultimately maximize comprehensive benefits.