What welding processes (such as submerged arc welding, gas shielded welding, etc.) are mainly used in steel structure product welding services?

In the manufacturing process of steel structure products, welding process is the core link of connecting steel and shaping the structural form, which is directly related to the strength, stability and service life of the product. Different welding processes are suitable for different steel types, structural forms and quality requirements, and professional steel structure manufacturers will flexibly select appropriate processes according to project requirements to ensure the balance between welding quality and production efficiency. As a professional equipment steel structure production factory with more than 10 years of welding manufacturing experience, Jiaxing Dingshi Machinery Manufacturing Co., Ltd has accumulated rich experience in the application and control of welding processes. Its German and European and American corporate customer groups also put forward strict standards for welding quality.

Arc welding (SMAW) is one of the most widely used processes in steel structure welding, also known as manual arc welding. This process uses the arc heat generated between the welding rod and the workpiece to melt the metal and form a weld by manually operating the welding rod. The advantages of arc welding are simple equipment and flexible operation. It is suitable for welding in various positions, whether it is flat welding, vertical welding, horizontal welding or overhead welding. It is especially suitable for complex structures and small-batch steel structures. In the manufacture of non-standard equipment steel structures, the flexibility of arc welding makes it an indispensable process due to the diverse shapes of workpieces and the changing welding positions.

Argon arc welding (TIG), or tungsten inert gas shielded welding, is a high-quality welding process. It uses tungsten as an electrode and uses inert gas (usually argon) to protect the molten pool and electrode to prevent air intrusion and weld oxidation. The weld of argon arc welding is beautiful, high-quality, and has small welding deformation. It is suitable for welding thin plates, high-alloy steels, and structural parts with extremely high welding quality requirements. In the manufacture of equipment steel structures, argon arc welding is an ideal choice for some key stress-bearing parts or parts with strict appearance requirements. German companies and European and American companies, these customers usually have more stringent requirements on welding quality. The advantages of argon arc welding in ensuring weld strength and aesthetics can be fully utilized, providing reliable guarantees for high-quality steel structure products.

Gas welding is a process that uses a flame generated by the combustion of a mixture of combustible gas and oxygen to heat the metal for welding. Commonly used combustible gases include acetylene, propane, etc. Gas welding equipment is light, low-cost, and relatively simple to operate. It is suitable for welding thin steel plates, copper pipes and other materials, as well as welding operations in places where there is no power supply. Although gas welding is not as widely used as arc welding and argon arc welding in large-scale steel structure welding, it still plays an important role in some specific scenarios, such as repairing small parts and welding of thin-walled structures. Jiaxing Dingshi Machinery Manufacturing Co., Ltd, as a steel structure production factory that provides one-stop service, uses gas welding as a supplementary process to meet the welding requirements of different products when dealing with diverse welding needs.

Laser welding is an advanced process that uses a high-energy-density laser beam as a heat source for welding. Laser welding has the advantages of fast welding speed, small heat-affected zone, small welding deformation, and high weld strength. It is suitable for welding precision structures, thin-walled materials, and difficult-to-weld materials. With the continuous improvement of the steel structure manufacturing industry's requirements for precision and efficiency, laser welding is increasingly widely used in the manufacture of high-end equipment steel structures.

In addition to the above-mentioned main welding processes, there are also processes such as submerged arc welding in steel structure welding. Submerged arc welding is a method of welding by burying the arc under granular flux. It has the advantages of high welding efficiency, stable weld quality, and good working conditions. It is suitable for long straight welds and large diameter circumferential welds of medium and thick plate structures. In the mass production of large steel structures, submerged arc welding can greatly improve welding efficiency and reduce production costs.

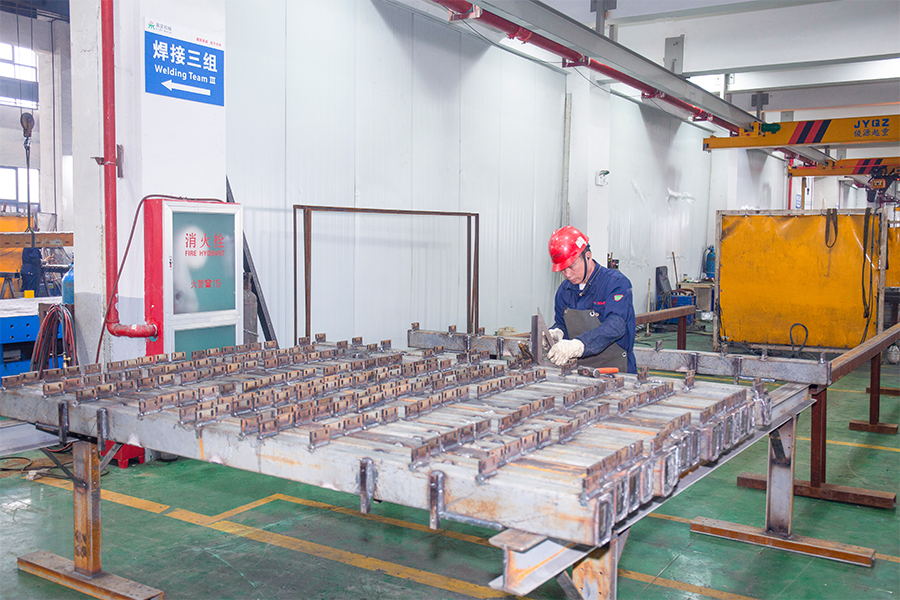

In the welding process, process control and quality monitoring are crucial. Through precise process parameter setting, strict welding process management and perfect quality inspection methods, ensure that each welded joint meets the highest strength and quality standards. The company has strong welding and manufacturing capabilities, and the annual output of non-standard equipment steel structures exceeds 10,000 tons. Behind this production scale is the proficient use of various welding processes and the ultimate pursuit of welding quality.

Jiaxing Dingshi Machinery Manufacturing Co., Ltd's strong technical support also provides a guarantee for the optimization of welding processes. The company has 20 professional factory technical designers with strong drawing design conversion capabilities, which can convert customer design requirements into reasonable welding process solutions to ensure that the welding process and product design are perfectly matched. In addition, the company has passed the quality management system certification. From raw material procurement, welding process formulation to finished product inspection, each link has a strict quality control process, providing a full range of guarantees for welding quality.