How Do Professional Steel Structure Painting Services Ensure High-Quality Surface Treatment for Complete Equipment?

In the modern equipment manufacturing industry, surface treatment processes play a decisive role in the service life, appearance texture, and environmental adaptability of equipment. Professional coating service providers, with advanced painting technologies and systematic service capabilities, can offer high-quality surface treatment solutions for various complete sets of equipment.

Refined Treatment Guarantees Core Product Performance

Steel structure painting services are committed to ensuring products have excellent durability, aesthetic appeal, and corrosion resistance through refined treatment. According to different material properties and application scenarios, advanced processes such as spraying and powder coating are flexibly adopted. Spraying technology uses high-pressure airflow to atomize the paint and evenly attach it to the workpiece surface, especially suitable for full coverage of complex-shaped components, easily handling painting needs of special structures such as curved surfaces and grooves. Powder coating, on the other hand, makes powder coatings firmly adhere to the substrate through electrostatic adsorption. After high-temperature curing, a dense coating is formed, which not only has strong adhesion but also has much lower VOC emissions than traditional solvent-based coatings, making it more advantageous in fields with strict environmental protection requirements.

Professional Configuration and Process Control for Coating Precision

To achieve precise coating effects, professional painting workshops are equipped with automated coating equipment and professional operation teams. Automated equipment can control the spraying path and paint dosage through preset programs, and adjust parameters in real-time with high-precision sensors to ensure uniform coating thickness everywhere. Professional technicians are proficient in the characteristics of different paints and can complete accurate color mixing according to color cards, achieving a high degree of reduction whether it is a standard color number or a custom color.

Strict process control is particularly important in coating services. After each coating project is completed, strict quality inspections such as coating thickness measurement, adhesion testing, and corrosion resistance testing are carried out. A coating thickness gauge is used to perform multi-point testing on different areas to ensure the thickness deviation is within ±5μm. The cross-cut test is used to check the bonding strength between the coating and the substrate to ensure no peeling or lifting occurs. Samples are placed in a salt spray test chamber to simulate harsh environments and test the corrosion resistance of the coating within a specified time, fundamentally ensuring the reliability and long-term effectiveness of the coating.

Hardware and Service Support for Enterprise Strength

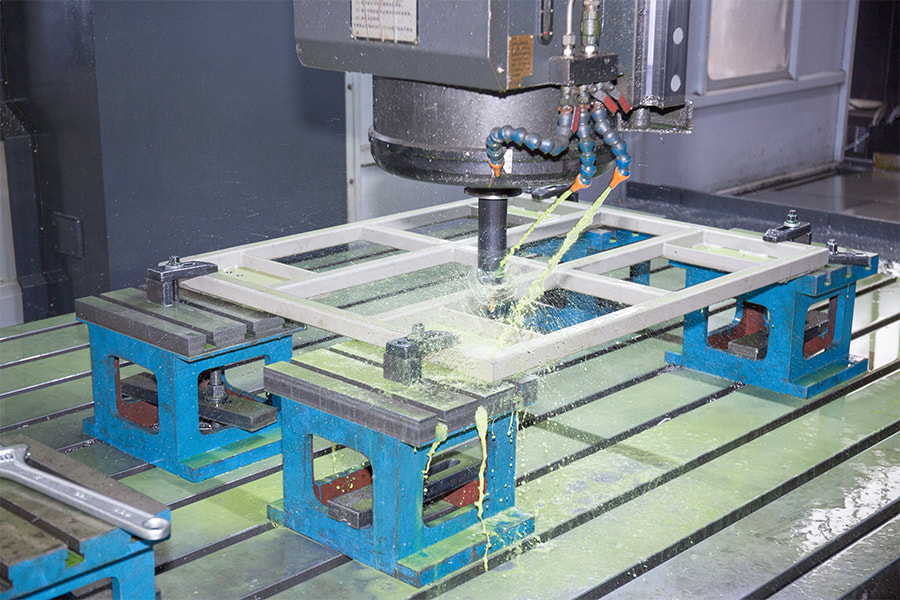

As a professional coating service provider, having a complete set of hardware facilities and perfect service capabilities is the key to ensuring service quality. A 15,000-square-meter factory can be divided into functional areas such as raw material area, pre-treatment area, coating area, inspection area, and finished product area, with each area connected by an automated conveying system to realize streamlined operations. The fixed assets include 30kW laser cutting machines, 20kW laser pipe cutting machines, 600-ton bending machines, various welding equipment, gantry machining centers, vertical machining centers, CNC lathes, shot blasting machines, spray booths, curing rooms, etc., forming a complete industrial chain from raw material processing to finished product coating.

The main business covers one-stop services such as cutting, bending, rolling, leveling, welding, machining, shot blasting, sandblasting, spraying, coating, and assembly, which can seamlessly connect the coating process with upstream and downstream links. For example, before coating steel structures, shot blasting and rust removal can be directly completed in the factory to avoid secondary pollution during workpiece transfer. After coating, assembly can be carried out simultaneously, reducing the time and cost consumed by customers in multi-link coordination and significantly shortening the project cycle.

Jiaxing Dingshi Machinery Manufacturing Co., Ltd., as a professional coating service provider, has always provided reliable and efficient professional coating services for various equipment with its technical advantages and service capabilities, ensuring excellent protection and high-quality appearance for equipment.