What comprehensive solutions can industrial and manufacturing equipment structures steel structural components provide?

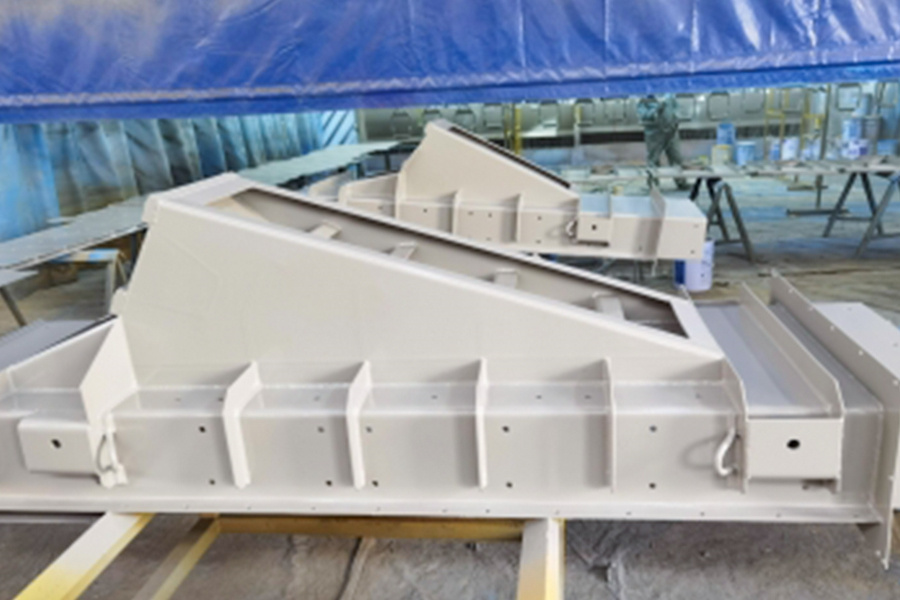

In the field of industrial and manufacturing equipment structures, professional steel structural component solutions cover a wide range, such as glass production machinery structures, vibration conveyor machinery structures, mining equipment components and engineering accessories. Jiaxing Dingshi Machinery Manufacturing Co., Ltd. can provide high-quality steel structural components for various industries, complex frames, beams, columns and other structural components, large platforms, precision machinery components, can be handled with advanced design and manufacturing capabilities, and ensure that the products have high strength and durability. The company's core support is reflected in many aspects: with an experienced technical team, it can provide customized production and processing services according to customer drawings and technical requirements; use high-quality materials and advanced processes to make products meet international standards, and ensure project success through strict quality control processes; and deliver products on time and with high quality to help customers improve production efficiency and product competitiveness.

How to ensure the quality and efficiency of non-standard customized industrial and manufacturing equipment steel structural components?

For non-standard customized industrial and manufacturing equipment steel structural components, Jiaxing Dingshi Machinery Manufacturing Co., Ltd. has multiple guarantees. The company has a clear commitment to non-standard customization and can carry out customized production and processing in strict accordance with the customer's drawings and technical requirements. With the guarantee of a professional team behind it, the experienced technical team can accurately understand customer needs and ensure that customized products meet expectations. In terms of quality, the company pays attention to the quality of surface treatment and coating, and adopts advanced technology to make the products not only beautiful, but also resistant to external erosion, and meet the quality standards of the high-end market. In terms of efficiency, with the guarantee of processing efficiency, it can quickly respond to customer needs, shorten the production cycle, and cooperate with efficient logistics delivery to ensure that non-standard customized products are delivered on time. At the same time, there is a cost-effective commitment, so that customers can obtain high-quality customized products while reducing costs.

What key role does the professional team play in the production of industrial and manufacturing equipment structures steel structural components?

The professional team of Jiaxing Dingshi Machinery Manufacturing Co., Ltd. plays a key role in the production of industrial and manufacturing equipment steel structural components. The team is experienced and can accurately interpret customers' drawings and technical requirements, provide strong support for non-standard customization, and ensure the accuracy and applicability of customized products. In the design stage, they can combine advanced design capabilities to handle complex structural components such as frames, beams, columns, etc., to ensure the high strength and durability of the products. In the production process, the professional team strictly controls each link, including the selection of materials and the execution of processing technology, to ensure that the products meet international standards and the company's high-end market quality positioning. They can also optimize the process according to the production situation, cooperate with the processing efficiency guarantee, ensure the delivery of products on time, lay the foundation for efficient logistics delivery, and then help customers improve production efficiency and product competitiveness.

How to ensure the advantages of industrial and manufacturing equipment structures steel structural components in surface treatment, coating quality, etc.?

Jiaxing Dingshi Machinery Manufacturing Co., Ltd. ensures the advantages of industrial and manufacturing equipment steel structural components in many aspects. In terms of surface treatment and coating quality, the company adopts advanced technology and strict operating procedures, and the professional team supervises the whole process to ensure that the coating is uniform and firmly adhered, improve the beauty of the product, and enhance its corrosion resistance and wear resistance, which meets the quality requirements of the high-end market. In terms of logistics delivery, the company has an efficient logistics delivery system. With precise control of production progress and good cooperation with logistics partners, combined with processing efficiency guarantee, it ensures that products can be delivered to customers on time and safely. The company's cost-effectiveness commitment also plays a role in these links. By optimizing the processes of surface treatment, painting and logistics, costs are reduced while ensuring quality, allowing customers to obtain higher cost-effectiveness. Professional teams participate in the whole process, providing solid guarantees for the smooth progress of these links.