No.158, Baoqun Road, Yaozhuang Town, Jiashan County, Jiaxing City, Zhejiang Province , China

In modern industrial production, efficient and stable material conveying is a cornerstone of ensuring production continuity and quality consistency. Vibrating conveying equipment, as a non-traditional conveying method, has gained widespread adoption across industries due to its advantages: simple structure, convenient maintenance, and adjustable conveying capacity. Its core lies in using vibration to drive materials’ directional movement—a process that, despite appearing straightforward, relies on complex mechanical principles and precise structural design. From basic kinematics to specific mechanical components, every detail shapes the equipment’s performance, efficiency, and reliability. Thus, a deep understanding of the key design elements of vibrating conveyor structures is crucial for optimizing their design and practical application. It is not merely about transporting materials from point A to point B, but about doing so in the most economical and reliable manner, handling diverse material properties and adapting to harsh working conditions.

The physics of vibration conveying is rooted in the clever application of inertial force. When a material-carrying trough vibrates periodically with a specific frequency and amplitude, its acceleration decomposes into horizontal and vertical components. Once the upward vertical acceleration exceeds gravitational acceleration in a certain phase, materials are “thrown” off the trough surface. In this moment, materials lose contact with the trough and continue moving forward due to inertia. As the vibration cycle proceeds, the trough moves downward and backward, while materials fall back to its surface under gravity—landing slightly ahead of their original position. This repeated “throw-fall” cycle enables continuous, stable material conveying.

A key parameter here is the “throwing coefficient,” determined by vibration frequency, amplitude, and the angle between the vibration direction and the horizontal plane. A well-calibrated coefficient is essential: too small, and materials fail to move effectively; too large, and excessive jumping occurs, increasing energy consumption and accelerating equipment wear.

The vibration is driven by vibrators, which convert electrical or mechanical energy into kinetic energy. Three main types dominate:

Elastic elements (coil springs, rubber dampers) are equally critical, storing energy and damping vibration. Efficient systems operate near resonance to maximize energy use from these elements, reducing vibrator power demands. Designing such systems requires balancing vibrator force, elasticity, damping, and trough geometry through rigorous mechanical analysis and simulation.

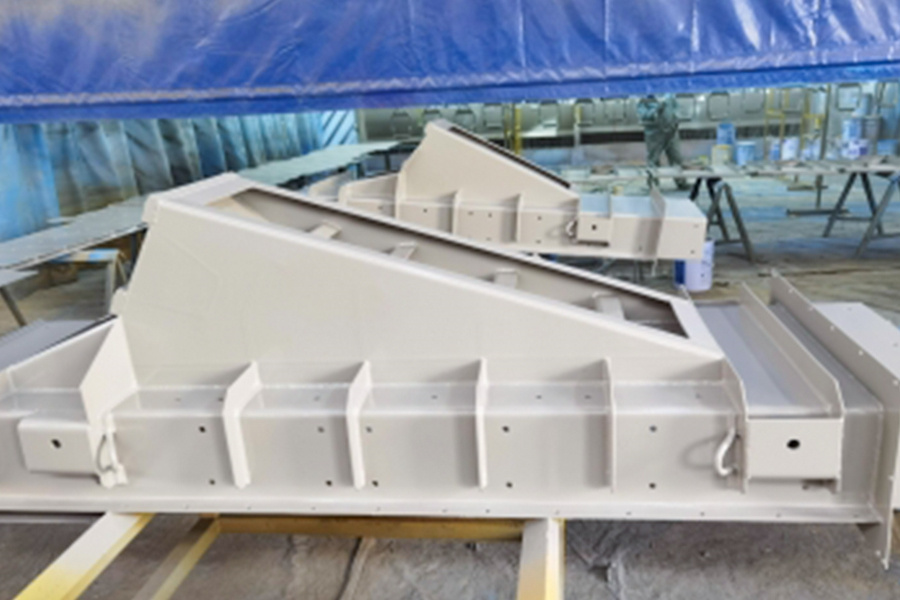

A vibrating conveyor’s performance depends not just on its vibrator, but also on the trough and support structure’s design—their geometry, materials, and connections directly affect efficiency, energy use, and longevity.

Trough design is paramount:

Inclination angle also matters: downward tilting uses gravity to accelerate conveying but risks uncontrollable flow, unsuitable for fragile materials; upward tilting enables lifting but requires higher vibration force, slowing movement.

Support structures must balance stability and vibration isolation. Frames need strength to bear equipment weight and vibration loads, while isolation springs or dampers contain vibration, preventing transmission to foundations or adjacent equipment—avoiding resonance or structural damage.

Modern design leverages finite element analysis (FEA) to model vibration modes, stress distribution, and fatigue life. This identifies weak points (e.g., stress concentrations at vibrator connections) for targeted reinforcement—adding stiffeners, adjusting materials, or modifying joins. FEA also mitigates resonance risks early, avoiding costly post-production fixes.

Reciprocating conveyors stand out for their gentle handling. Unlike high-frequency vibrators, their “slow-push, fast-return” motion minimizes material impact, making them indispensable for fragile goods: biscuits, pharmaceuticals, or casting sand cores, where preserving integrity is critical.

They also excel at maintaining material uniformity. Their low-disturbance motion prevents segregation of mixed particles (by size or density)—vital in chemicals or construction, where blend consistency matters.

However, their design is complex. Precision crank-linkages or hydraulic systems generate the required asymmetric motion, while robust damping (e.g., heavy inertia blocks or hydraulic dampers) counteracts large inertial forces. This ensures quiet, stable operation and protects support structures.

Vibrating conveyors operate under high speeds, loads, and cyclic stress, so proactive maintenance is key. Common issues include:

Diagnosis combines visual checks (cracks, loose parts), vibration/amplitude measurements (using meters or sensors), and temperature monitoring (overheating indicates lubrication or bearing issues).

Maintenance strategies include:

For problematic materials—fine powders, sticky granules—combining vibration with fluidization boosts efficiency. Airflow through a porous trough bottom suspends particles,reducing friction and preventing agglomeration. Vibration complements this by driving movement, with parameters (frequency, amplitude, airflow) calibrated to balance fluidization and stability.

This hybrid system doubles as a vibrating fluidized bed, enabling in-conveying drying/cooling via temperature-controlled airflow. It is invaluable in chemicals, pharmaceuticals, and food processing, handling diverse materials with unmatched versatility.

In essence, vibrating conveyors’ success stems from mastering their mechanics, optimizing structures, and adapting to material needs—making them a cornerstone of modern industrial efficiency.

Welding is a fundamental process in the manufacturing and construction industries, pa...

READ MORE

Introduction In the world of equipment manufacturing, structural integrity, cost-effe...

READ MORE

In the world of industrial manufacturing, the selection of materials plays a pivotal ...

READ MORE

Steel structures play a crucial role in modern industrial and manufacturing environme...

READ MORE